- Home

- Home_de

- Products

- Downloads

- Forum

- Sales

- News

- Exhibitions

- Know how

- Building VP-2500D workingtable

- First installation

- VP-2500D 0402 placement test

- Mark detection demo

- Placing TQFP48 demo

- 0201 Placement

- BGA Alignment

- FAQ-Feeder-settings

- Soldering-FAQ

- Controller Upgrade V1 to V2

- How to upgrade to 19 slot nozzle changer

- First setup and placement job

- How to build Electronics

- For Makers

- Questions & Answers

- Software

- Repair Documents

- References

- Service

- Spare-Parts

- Videos

- Warranty

- Kompetenz

- Competence

- Cookie Policy

- Privacy Policy

- About

- PANDA-design-contest

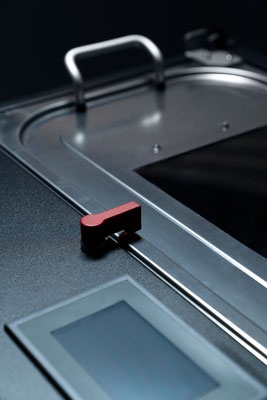

BSC JUST-SOLDER 460

Made in Germany

For beginners and professionals

In the development of the JustSolder 460, it was important to us that the soldering system offers a lot while remaining easy to use.

What emerged is a well-coordinated and reliable hardware with operation through a touch color display. The software is straightforward, and the menu navigation is intuitive.

We have integrated a predefined soldering program so that soldering can be done immediately without prior knowledge.

Professionals appreciate the customization options to create and adjust soldering profiles. Additionally, soldering curves can be displayed and saved to compare changes effectively.

Precision soldering

The JustSolder 460 ensures precise control of soldering parameters.

This enables optimal solder connections with high repeatability, even in small quantities.

This is particularly important to guarantee consistent quality.

The soldering process can be adjusted by you to specific requirements, allowing you to solder challenging components with confidence.

The vapor phase technology of the soldering system enables uniform heat distribution in the soldering process. Therefore, various components with different thermal requirements can be easily

soldered simultaneously.

The Just Solder 460 comes with a temperature sensor, which can measure temperatures in the unit or directly on the board. The soldering device can be optionally expanded with an additional

temperature sensor.

Temperatures are displayed in real-time and can also be presented as a curve.

Traceable

Save your soldering curves, as well as all parameters and settings, by taking a screenshot.

Simply execute the "Save" command on the touch panel, and the control system automatically saves the screen content to a USB storage device.

The USB port is conveniently located on the top of the soldering system.

This way, soldering curves can be assigned and documented for the soldered assemblies.

Efficient

Thanks to vapor phase technology and an efficiency-optimized design, only minimal energy is required for soldering. A complete soldering cycle consumes only 0.25 kWh!

Large systems in productions typically require a lot of energy for heating and cooling, and this can be saved with a Just Solder 460. This is environmentally friendly and significantly reduces

the costs for soldering small quantities and prototypes. The Just Solder 460 gladly handles:

Soldering trials and production approvals

Small batches, samples, prototypes

Subsets (e.g., due to unavailability of components)

Assemblies that are difficult to solder (especially if "only" reflow convection ovens are available)

BSC JUST SOLDER 460 Vapor-Phase-Reflow oven

SMT / SMD prototype soldering oven with vapor phase technology

Dimensions:

590 x 540 x 350 mm (l*w*h)

Weight:

25 kg

Recommended clearance:

Left / right / behind each 300 mm

Power connection:

208-240 VAC, 50/60 Hz

(Power quality according to EN50160)

Recommended fuse protection: 10 Amps

Maximum electrical power.: 1750 W

Power consumption per cycle: app. 0,25 kWh

Connection cable: CEE 7/4 Schuko 2,5 m (included)

Noise level:

<70 dB

Maximum soldering material format:

460 x 205 x 100 mm (l*w*h)

or 385 x 265 x 100 mm (l*w*h)

Maximum weight of soldering material: 3 kg

Process temperature:

165-240° C (depending on kind of Galden)

Galden filling quantity.: 0,9 - 1,2 kg

Cooling: Air-cooled

Display: 4,3" Touch HMI

Data-interface: USB

$3,800.00

Final price excl. shipping costs

Free shipping to the following countries: Show more Show less

- 25 kg

- Available

- Ships within 3-5 weeks1