- Home

- Home_de

- Products

- Downloads

- Forum

- Sales

- News

- Exhibitions

- Know how

- Building VP-2500D workingtable

- First installation

- VP-2500D 0402 placement test

- Mark detection demo

- Placing TQFP48 demo

- 0201 Placement

- BGA Alignment

- FAQ-Feeder-settings

- Soldering-FAQ

- Controller Upgrade V1 to V2

- How to upgrade to 19 slot nozzle changer

- First setup and placement job

- How to build Electronics

- For Makers

- Questions & Answers

- Software

- Repair Documents

- References

- Service

- Spare-Parts

- Videos

- Warranty

- Kompetenz

- Competence

- Cookie Policy

- Privacy Policy

- About

- PANDA-design-contest

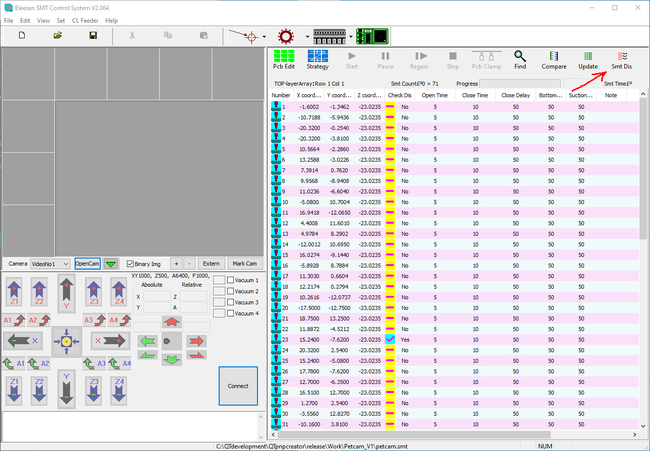

V2 Software BLOG

V2.078

- Bug fix for new vision models cap / resitor / diode when placement angle was zero

- for small parts the angle precision setting need to be increased!

V2.077

- New USB camera option added to the "Camera List / Management" dialog

- Our software supports now standard UVC HD USB cameras

Analog cameras:

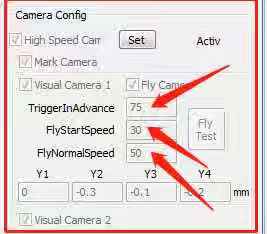

If you upgrade old installion you need to do additional settings in camera setting dialog to enable analog camera usage.

Press the Activ button to enable settings first. Adjust all cameras to CameraCCD and check the use No. settings too.

Click OK button and close dialog.

Don't forget to click save button too and restart application.

For USB Cameras use CameraUSB mode and for our industrial cameras used in 4R and Pecker machines us CameraHD switch.

V2.076a

- Bug fix S33-S64 feed command not responding fixed

V2.076

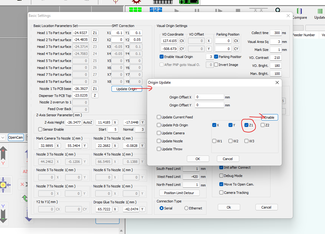

- Pickup position and camera position now updated by visual origin function.

- New option in manual movement area right click menu to automatically update - manual mark point correction and reset offsets.

- CL feeder automatically opened if pickup to camera command executed.

- New function in Feeder dialog “Back To Feed” send part back to feeder

- Bug fix nozzle sort order during placement and sorting fixed (1,10,11,12,13 .. issue).

V2.075

- New Vision mode order need to adjust your data

00:General

01:Resistance

02:Capacitance

03:Diode

04:Triode

05:FootEdge1

06:FootEdge2

07:FootEdge4

08:BGA-TriangleMark

09:BGA-4PointAngle

10:BGA-4Chamfer

11:BGA-1Chamfer

12:BGA-Other

13:Special

- Dispenser mode support panels now

- Manual move Speed used now if you click in vision output

- PNP Data grid all fields locked now except mount flag and feeder assignment

- UI locked during machine homing

a+b some bug fixes regarding Reset sequence

V2.074

- Pecker BIN files updated in CAN-Feeder and SPI-Feeder version

- Feeder data CSV export / import function bug fixed

V2.073

- Manual Mark Point function improved

- Raptor manual Z-Axis movement direction in feeder dialog fixed

- Nozzle list in feeder dialog fixed

- Z-axis position did not update in feeder dialog fixed

- Nozzle head shift function if position can't get reached by selected head improved

- Feeder data CSV export / import function

- Feeder used on project mark function

[e] Bin file update for V3 controller

[f] Clamp Button permanently enabled for Raptor machines

DLL updates

V2.071

- Bug fix for push feeder problem if part purged the next feed cycle got mixed up.

- Manual mark point correction updated to apply offset for manual position checking read manual for final description

V2.070

- Bug fixes because of VC2015 Framework upgrade

- Feeder editor crash fixed

- Crash during vision alignment fixed

- New head usage algorythm if head 1 can't reach feeder position it take over to H2 >> H3 >> H4 to check if any head can reach position.

- Add feeder group crashes software fixed

- Add grid box crashe software fixed

V2.069

- Application updated to VC++ 2015

- V3 Controller move distance limitation changed from 65535 to 32Bit

- preparing new vision functions by updating the OpenCV library

- fixed some new installer issues 22.10.2022

- Update installation has installer now too

- Setup will backup the configuration files to backup folder prior install

V2.068

- Feeder position error added to status window if head can't reach the pickup position

- V3 controller bin files for PECKER updated

- RAPTOR in head replacement mode rotation angle was set incorrectly error fixed

- Feeder Import and export to CSV function

V2.067

- Head replacement mode added (RAPTOR)

If head 1+2 can't reach pickup position on West head 3+4 used.

If head 7+8 can't reach pickup poisition on East head 5+6 used.

- Quick fix to support vacuum offset values from Basic setting for V3 controller

V2.066

- CL Feeder can't keep open bug on old firmware versions fixed

- new V3 Firmware update functions added

V2.065

- new dispenser MODE2 function

- manual updated for dispenser functions

- fixing stability issues

- automatic head swap function on 4 head machine fixed when accessing east feeder 05.01.2022

- vacuum measuring function crash fixed 06.01.2022

- dispenser operation freeze fixed 06.01.2022

V2.065b

- camera simulation bug on 4 head machines while accessing east feeder bug fixed 07.01.2022

- Breaks happened in dispenser mode fixed 07.01.2022

- translation problem fixed in nozzle list 07.01.2022

V2.065c 25.01.2022

- When the first head vacuum fails, the second element rotates when it reaches the camera bug fixed.

Take care the machine axis check enabled for Z1 (2head) and Z1+Z2 (4 head machine).

If not checked the axis will not initialize in this version.

Take care Offset X / Y is zero before clicking ok!

V2.064

- new dispenser coordinates view

V2.063b

- bug correction for 0402 push feeder mode

- locked dialogs when conveyor mode is active during PNP processing

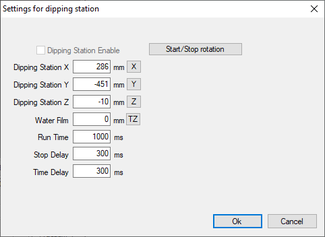

- added move to dipping station coordinate command

V2.062

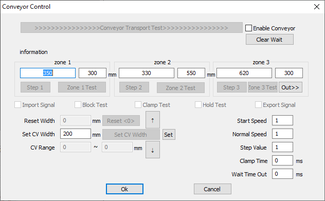

Conveyor dialog updated for new 2021 conveyor version!

Firmware V2.07 required.

FLUX Dipping station support implemented.

Firmware V2.07 required.

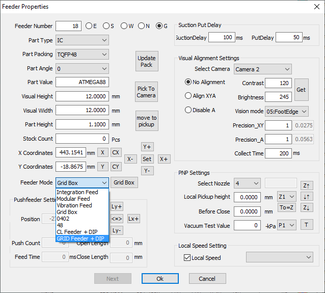

New feeder modes added to support dipping station usage if parts taken from CL or GRID feeder.

Support for Z axis sensor added too.

Firmware V2.07 required.

V2.061

- support for Z-Axis sensor added (Firmware V2.07 required.)

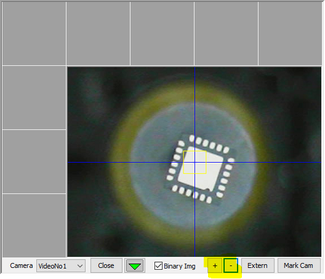

- pick to camera function in feeder setup added

- new brightness setting parameter added

- zoom buttons added in video output panel for touch control

Pick to camera function

Zoom buttons

V2.060

- new automatic measurement features in camera list added right click menu on camera in camera list

- Please open camera configuration for each camera and save again then restart software.

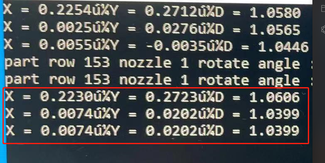

- vision log file shows X/Y position deviation and diameter D

- bug fix for visual area size wrong for first part in placement

- bug fix if visual zoom entered as float in camera list the visual area calculation got

wrong

- bug fix precision and vacuum error got mixed (precision error shown if vacuum too low)

Vision log file shown

It shows X/Y position deviation and measured diameter D

V2.059

- bug fix part size check removed

- Move to drop box close vacuum now

- Mesurements shown on camera overlay

- translations updated

V2.058

- Brightness of mark camera not get updated by feeder edit dialog opening

- new additions for 8 head machine

- video output window changed for additional heads

- camera settings dialog data problem solved (04.01.2021)

V2.057

- bug fix for vacuum switch problem on head 4 caused by new dispenser functions.

V2.056

- Error message changed it show vacuum error if no part under nozzle and precision error if part can’t get aligned

V2.055

- Adding a new part to the package database Storage problem solved where a field was only saved the second time.

- New function added to avoid use of head 3+4 on west feeder and head 1+2 on east vibration feeder for VP2800HP-CL64 machines.

- New movement scheme to avoid colissions with 19 slot nozzle changer wen taking tall parts from vibration feeder on east side.

- Clear messages for vacuum and precision error added.

- 8 head machines settings added

V2.054

- Problem machine stopped over bottom HD camera solved.

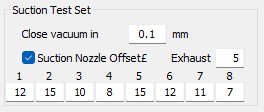

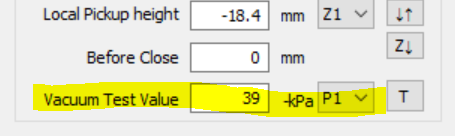

- We added vaccum value retrieve dropdown box to feeder dialog to take over vacuum value from Head 1 - 4

V2.053

- Logfile switch added to CPU Version settings dialog showing vision processing

- Vision option BGA Triangle function updated

- Copy back to part database button added in feeder dialog

- SOT-23 alignment improved

- Manual updated!

- Clamp button added for conveyor use

V2.052

Bug fixes:

- If first PCB in panel setup switched off the mark point position shift

- Visual origin detection problem fixed for HD camera machines

- HD Camera 2 caused problem if visual area in feeder too big

V2.051

Bug fixes:

- Head 3 pickup part bug fixed

- X/Y position automatical switched to pulse count fixed

- Grid box CX / CY button take over relative position to Grid box origin.

V2.050

Modifications:

- 16 slot nozzle changer added

Bug fixes:

- missing rotation bug on second pickup for head 2 after pickup error

V2.049

- nozzle changer problem solved when fixed head 1 or fixed head 2 mode used

- winder speed setting issues removed

V2.048

Bug fixes:

- Open mark camera when using feeder command "move to pickup position"

- Data upgrade issue fixed when local speed enabled and set to mount speed

Modifications:

- New button in feeder dialog to move camera to pickup position

V2.047

Bug fixes:

If nozzle send to part coordinate head 1 - x will get adressed corresponding to feeder settings if no nozzle changer enabled. If nozzle changer enabled always head 1 send to location. (finished)

Mount selection now works on all PCB's in a panel setup. (finished)

If parts out during vibration feeder pickup and feed count set the machine software freeze problem fixed. (finished)

Panel Mark detection problem when X1==X2 or Y1==Y2 coordinate. (still under work)

Modifications:

- All TAB orders sorted again

- Increment and decrement buttons working in all dialogs

- Package database dialog is resizebale now and parts sorted by part name

- Package database sorting added by column header click

- Take over camera parameter button added for mark points

- Take over camera parameter button added for mark points

- Parameter validation checkings improved in feeder dialog

- Reset speed modification locked by default now!

- New camera tracking function enabled in basic settings, move camera to pickup position when feeder settings edited, or to part location in pnp list if part location edited.

- single push feeder feed button in feeder dialog added

V2.046R1

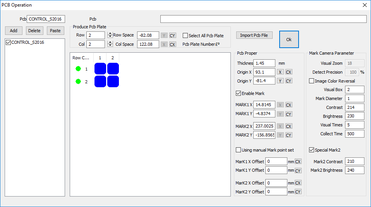

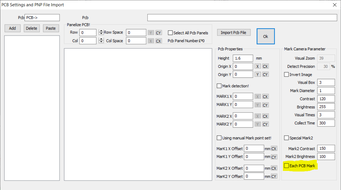

New Panel Mark Detection function

New option in PCB settings to support fiducial / mark point stepping in panel setups. First PCB mark points set and if function enabled mark test will applied to each PCB in a panel before placement.

We offer two modes of mark detection based on panel or single PCB. Mark points per panel or single PCB means a pair of points in opposite edges to align the Placement data. It’s important to find the mark point position on first master PCB using the vision functions and take over the given position to PCB settings mark point position!

Grid feeder setup changed

Bug fixes in feeder setup dialog! If grid feeder first time selected during new feeder setup, the software ask to save feeder first before you can open the grid feeder settings.

Vibration feeder bug solved! If part failed during alignment or vacuum test the next part picked up can't get well aligned.

Fly by Camera mode for HD cameras

New Fly by Camera option for bottom camera 1 added. This function is only possible for the VP-2800HP-4R using the HD camera setup. The parts on all 4 heads in a row get aligned during machine head move over the bottom camera 1. This fast option is used for resistors, capacitors and LED to speed up the placement process.

This bug fixed too!

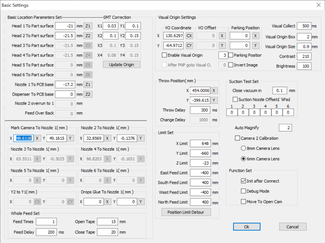

New axis collision prevention function

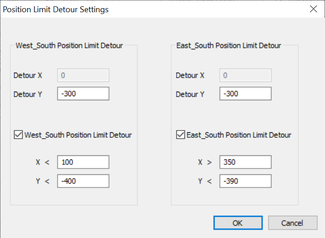

New botton to open the position limit detour function.

This new function is used to prevent collisions when machine is moving from West to East side for pickup parts on second head. It needs to avoid the nozzle changer cart.

There are 2 limit detectors West_South and East_South Position Limit Detour.

If limit setting X/Y reached the machine execute the additional move command to retract the Y-axis.

The retraction distance setting is Dertour Y settings. You can set individual for West and East axis.

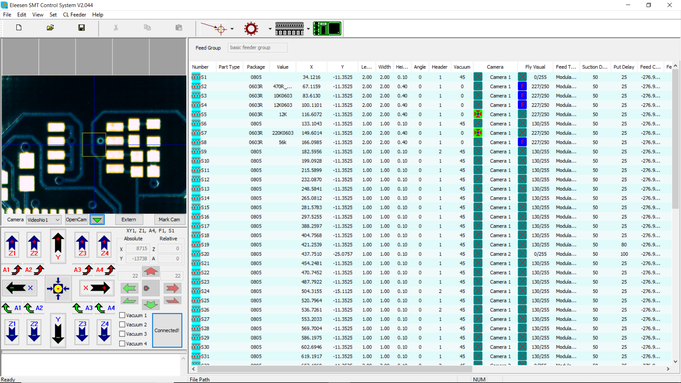

V2.044

- UI improvements

- Update needed for new machine controller functions

- HD Cameras now integrated

- Vibration feeder supports push count to do interval feeds 2x 50ms for example drive 50ms on, 50ms off, 50ms on, 50ms off

- bug fixes for connection problems

V2.043

- Extended security features for CPU Version V2.05 & V2.06

- Limit switch detection improved

- Conveyor dialog added

V2.042

- Fixed bug for visual origin detection the brightness and contrast settings now taken from "Basic Settings"

- Added a visual area parameter for Visual Origin detection in "Basic Settings"

- New Parking position option in Basic settings

- Fixed BGA mark suppression in visual alignment options

V2.039

- Fixed bug in panel position correction

- Add speed limiter in speed settings dialog

- Fixed some issues for speed management added in V2.035

- Open / Close video now on single click again

- Button added in feeder editor to open / close CL feeder (don't forget to close again after settings finished)

V2.035

New settings for Dispenser in Basic Settings and Strategy Settings dialogs.

Software manual updated.

Axis movement buttons in feeder dialog.

Z axis can get moved using 3 new buttons now and Z axis selection drop down box added!

Since V2.035 you need to open the CL feeder before setting pickup position using manual control. The same for pick to visual camera

function!

We add new button function for open / close CL feeder soon!

V2.034

Feeder selection drop down list in PNP list view has now 2 columns and showing part name too.

Package database has new fields now plus selective updates by check box.

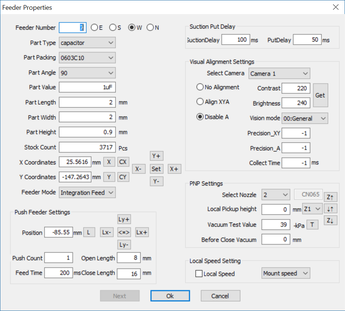

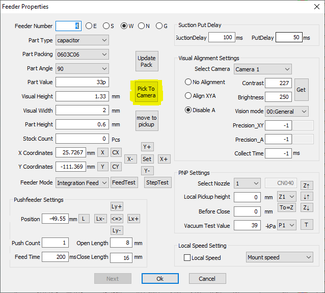

Feeder has vision precision settings now.

New find function in PNP list

New compare function in PNP list to show differences in part names of assigned feeder.

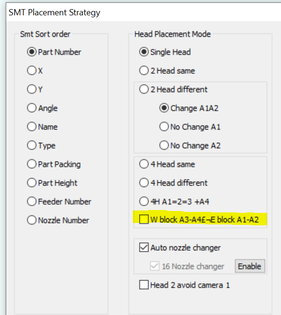

New double head placement strategy

PNP file matching field now Part name and Part packing possible

V2.032

New Zoom function on mouse wheel for video output window.

New switch to bigger vision output image by extern button

New Mouse click in vision window moves machine X and Y axis.

New STRG + cursor keys move machine X and Y axis.

New Dispenser head support to save nozzle changer cart against collisions.

New Feeder assignment compare and update function

V2.031

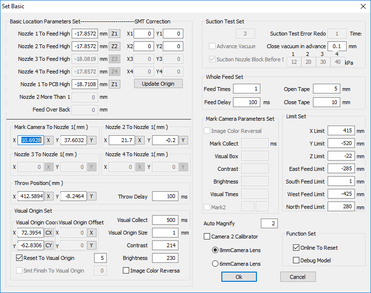

Bug fixing, Machine origin by mark detection added, compensation settings for each head and camera, mark settings in project files now, Grid box handling improved move to box possible now.

Vision models added.

Visual Origin Set to improve the precision of machine origin. You can add a mark point in the working area and the machine will detect this mark point and adjust the machine origin if enabled.

Update Origin function to shift all machine positions together.

V2.031

1. Vision Models added to feeder settings

2. Push feeder head move to zero position on pickup error.

3. Camera / digitizer support updated higher resolutions possible.

4. Alignment settings changed.

V2.030

- Special mark points added to support center points for IC before placement.

- Move head to drop position added.

- Update Feeder button for PNP list added.