- Home

- Home_de

- Products

- Downloads

- Forum

- Sales

- News

- Exhibitions

- Know how

- Building VP-2500D workingtable

- First installation

- VP-2500D 0402 placement test

- Mark detection demo

- Placing TQFP48 demo

- 0201 Placement

- BGA Alignment

- FAQ-Feeder-settings

- Soldering-FAQ

- Controller Upgrade V1 to V2

- How to upgrade to 19 slot nozzle changer

- First setup and placement job

- How to build Electronics

- For Makers

- Questions & Answers

- Software

- Repair Documents

- References

- Service

- Spare-Parts

- Videos

- Warranty

- Kompetenz

- Competence

- Cookie Policy

- Privacy Policy

- About

- PANDA-design-contest

- New V3 software

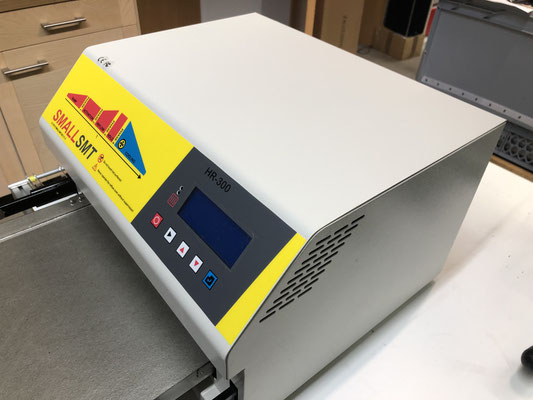

Hot Air Reflow oven HR-300

The HR-300 is an extremely user-friendly convection oven suitable for lead-free SMD soldering of printed circuit boards.

It has many advantages especially fully controlled reflow cycle in closed oven!

HR-300 functional description:

The special feature of this reflow oven is that the complete cycle takes place in a closed oven.

We have 2400W heating power and hot air circulation to ensure even heat distribution.

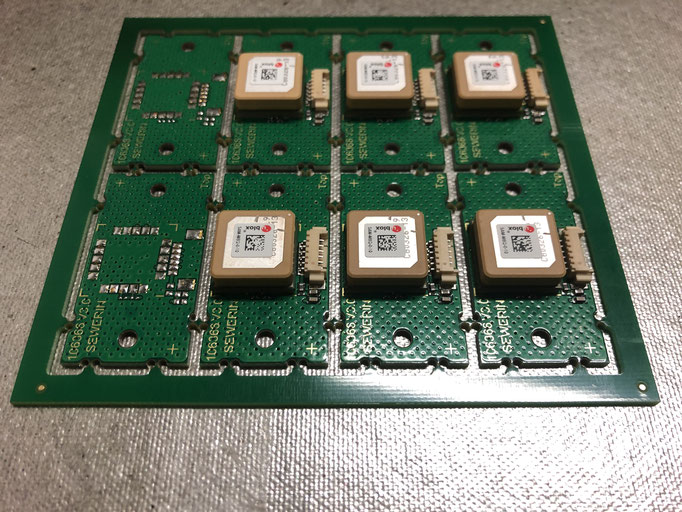

Even complicated components like GPS antennas or BGA's can be soldered very well.

As this reflow oven has an exhaust fan, the exhaust gases can be exhausted from the room via a 100mm hose.

All parameters are easy to set and only the temperature to be reached and the dwell time have to be set.

The duration of the heating phase is dynamic until the target temperature is reached, then the fixed holding time expires.

A special feature is the controlled cooling which also reheats when the temperature drops too quickly.

Our HR-300 reflow oven is the perfect solution for prototype production and as a supplement to a vapour phase.

The constant temperature mode can be used to bake components!

Ovens are shipping from Germany.

Technical data:

Reflow oven chamber size is 400x310mm.

New 110V / 1800W version added!

Please ask sunny@smallsmt.biz for download password.

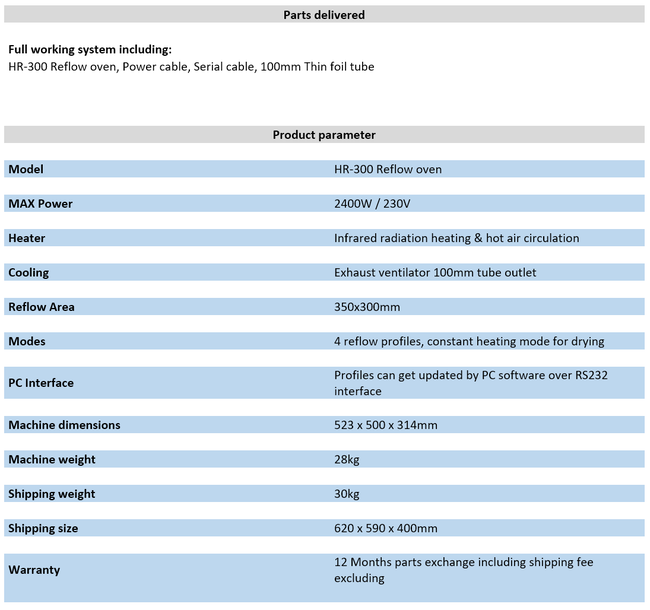

HR-300 230V

Prices will be communicated on request!

POWER SUPPLY: 230V

MAX POWER: 2400W

HEATER: Infrared radiation heating & hot air circulation

COOLING: Exhaust ventilator 100mm tube outlet

REFLOW AREA: 350x300mm

MODES: 4 reflow profiles, constant heating mode for drying

PC INTERFACE: Profiles can get updated by PC software over RS232 interface

DIMENSIONS: 523 x 500 x 314mm

WEIGHT: 28Kg

$0.00

Final price, free shipping to selected countries

Free shipping to the following countries: Afghanistan, Albania, Andorra, Angola, Anguilla, Antarctica, Antigua and Barbuda, Armenia, Netherlands Antilles, United Arab Emirates , Algeria, American Samoa, Argentina, Aruba, Australia, Austria, Azerbaijan, Bahamas, Bahrain, Bangladesh, Barbados, Belarus, Belgium, Belize, Benin, Bermuda, Bhutan, Bolivia, Bosnia and Herzegovina, Botswana, Bouvet Island, Brazil, British Indian Ocean Territory, British Virgin Islands, Brunei, Bulgaria, Burkina Faso, Burundi, Cambodia, Cameroon, Canada, Cape Verde, Cayman Islands, Central African Republic, Chad, Chile, China, Christmas Island, Cocos [Keeling] Islands, Colombia, Comoros, Congo - Brazzaville, Congo - Kinshasa, Cook Islands, Costa Rica, Côte d’Ivoire, Croatia, Cuba, Cyprus, Czech Republic, Denmark, Djibouti, Dominica, Dominican Republic, Ecuador, Egypt, El Salvador, Equatorial Guinea, Eritrea, Estonia, Ethiopia, Falkland Islands, Faroe Islands, Fiji, Finland, France, French Guiana, French Polynesia, French Southern Territories, Gabon, Gambia, Georgia, Germany, Ghana, Gibraltar, Greece, Greenland, Grenada, Guadeloupe, Guam, Guatemala, Guinea, Guinea-Bissau, Guyana, Haiti, Heard Island and McDonald Islands, Honduras, Hong Kong SAR China, Hungary, Iceland, India, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, Kiribati, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Lesotho, Liberia, Libya, Liechtenstein, Lithuania, Luxembourg, Macau SAR China, Macedonia, Madagascar, Malawi, Malaysia, Maldives, Mali, Malta, Marshall Islands, Martinique, Mauritania, Mauritius, Mayotte, Mexico, Micronesia, Moldova, Monaco, Mongolia, Montenegro, Montserrat, Morocco, Mozambique, Myanmar [Burma], Namibia, Nauru, Nepal, Netherlands, New Caledonia, New Zealand, Nicaragua, Niger, Nigeria, Niue, Norfolk Island, Northern Mariana Islands, North Korea, Norway, Oman, Pakistan, Palau, Palestinian Territories, Panama, Papua New Guinea, Paraguay, Peru, Philippines, Pitcairn Islands, Poland, Portugal, Puerto Rico, Qatar, Réunion, Romania, Russia, Rwanda, Saint Barthélemy, Saint Helena, Saint Kitts and Nevis, Saint Lucia, Saint Martin, Saint Pierre and Miquelon, Saint Vincent and the Grenadines, Samoa, San Marino, São Tomé and Príncipe, Saudi Arabia, Senegal, Serbia and Montenegro, Seychelles, Sierra Leone, Singapore, Slovakia, Slovenia, Solomon Islands, Somalia, South Africa, South Georgia and the South Sandwich Islands, South Korea, Spain, Sri Lanka, Sudan, Suriname, Svalbard and Jan Mayen, Swaziland, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Timor-Leste, Togo, Tokelau, Tonga, Trinidad and Tobago, Tunisia, Turkey, Turkmenistan, Turks and Caicos Islands, Tuvalu, Uganda, Ukraine, United Kingdom, United States, Uruguay, U.S. Minor Outlying Islands, U.S. Virgin Islands, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Wallis and Futuna, Western Sahara, Yemen, Zambia, Zimbabwe Show more Show less

- 28 kg

- Available

- Ships within 1-3 days1

HR-300 110V

Prices will be communicated on request!

POWER SUPPLY: 110V

MAX POWER:1800W

HEATER: Infrared radiation heating & hot air circulation

COOLING: Exhaust ventilator 100mm tube outlet

REFLOW AREA: 350x300mm

MODES: 4 reflow profiles, constant heating mode for drying

PC INTERFACE: Profiles can get updated by PC software over RS232 interface

DIMENSIONS: 523 x 500 x 314mm

WEIGHT: 28Kg

$0.00

Final price, free shipping to selected countries

Free shipping to the following countries: Afghanistan, Albania, Andorra, Angola, Anguilla, Antarctica, Antigua and Barbuda, Armenia, Netherlands Antilles, United Arab Emirates , Algeria, American Samoa, Argentina, Aruba, Australia, Austria, Azerbaijan, Bahamas, Bahrain, Bangladesh, Barbados, Belarus, Belgium, Belize, Benin, Bermuda, Bhutan, Bolivia, Bosnia and Herzegovina, Botswana, Bouvet Island, Brazil, British Indian Ocean Territory, British Virgin Islands, Brunei, Bulgaria, Burkina Faso, Burundi, Cambodia, Cameroon, Canada, Cape Verde, Cayman Islands, Central African Republic, Chad, Chile, China, Christmas Island, Cocos [Keeling] Islands, Colombia, Comoros, Congo - Brazzaville, Congo - Kinshasa, Cook Islands, Costa Rica, Côte d’Ivoire, Croatia, Cuba, Cyprus, Czech Republic, Denmark, Djibouti, Dominica, Dominican Republic, Ecuador, Egypt, El Salvador, Equatorial Guinea, Eritrea, Estonia, Ethiopia, Falkland Islands, Faroe Islands, Fiji, Finland, France, French Guiana, French Polynesia, French Southern Territories, Gabon, Gambia, Georgia, Germany, Ghana, Gibraltar, Greece, Greenland, Grenada, Guadeloupe, Guam, Guatemala, Guinea, Guinea-Bissau, Guyana, Haiti, Heard Island and McDonald Islands, Honduras, Hong Kong SAR China, Hungary, Iceland, India, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, Kiribati, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Lesotho, Liberia, Libya, Liechtenstein, Lithuania, Luxembourg, Macau SAR China, Macedonia, Madagascar, Malawi, Malaysia, Maldives, Mali, Malta, Marshall Islands, Martinique, Mauritania, Mauritius, Mayotte, Mexico, Micronesia, Moldova, Monaco, Mongolia, Montenegro, Montserrat, Morocco, Mozambique, Myanmar [Burma], Namibia, Nauru, Nepal, Netherlands, New Caledonia, New Zealand, Nicaragua, Niger, Nigeria, Niue, Norfolk Island, Northern Mariana Islands, North Korea, Norway, Oman, Pakistan, Palau, Palestinian Territories, Panama, Papua New Guinea, Paraguay, Peru, Philippines, Pitcairn Islands, Poland, Portugal, Puerto Rico, Qatar, Réunion, Romania, Russia, Rwanda, Saint Barthélemy, Saint Helena, Saint Kitts and Nevis, Saint Lucia, Saint Martin, Saint Pierre and Miquelon, Saint Vincent and the Grenadines, Samoa, San Marino, São Tomé and Príncipe, Saudi Arabia, Senegal, Serbia and Montenegro, Seychelles, Sierra Leone, Singapore, Slovakia, Slovenia, Solomon Islands, Somalia, South Africa, South Georgia and the South Sandwich Islands, South Korea, Spain, Sri Lanka, Sudan, Suriname, Svalbard and Jan Mayen, Swaziland, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Timor-Leste, Togo, Tokelau, Tonga, Trinidad and Tobago, Tunisia, Turkey, Turkmenistan, Turks and Caicos Islands, Tuvalu, Uganda, Ukraine, United Kingdom, United States, Uruguay, U.S. Minor Outlying Islands, U.S. Virgin Islands, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Wallis and Futuna, Western Sahara, Yemen, Zambia, Zimbabwe Show more Show less

- 28 kg

- Available

- Ships within 1-3 days1

Example Profiles

Loctite GC10

| GC10 Example | Temperature | Time |

| READY | 100°C | 01:00 |

| HEAT | 210°C | 00:30 |

| WELD | 240°C | 00:10 |

| HOLD | 220°C | 00:05 |

| COOL | 100°C | 00:00 |

Artikelnummer:2376530089554

|

Felder |

Temperature | Time |

| READY | 100°C | 01:00 |

| HEAT | 200°C | 00:30 |

| WELD | 230°C | 00:10 |

| HOLD | 210°C | 00:05 |

| COOL | 100°C | 00:00 |

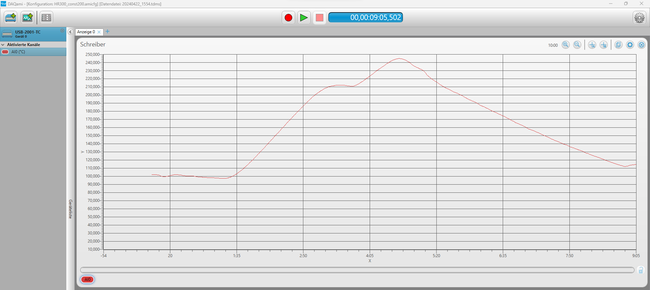

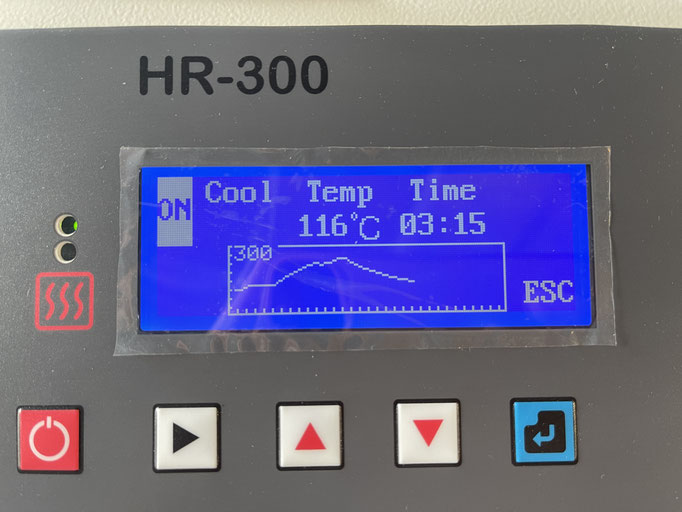

Measured Temperature in machine using this profile

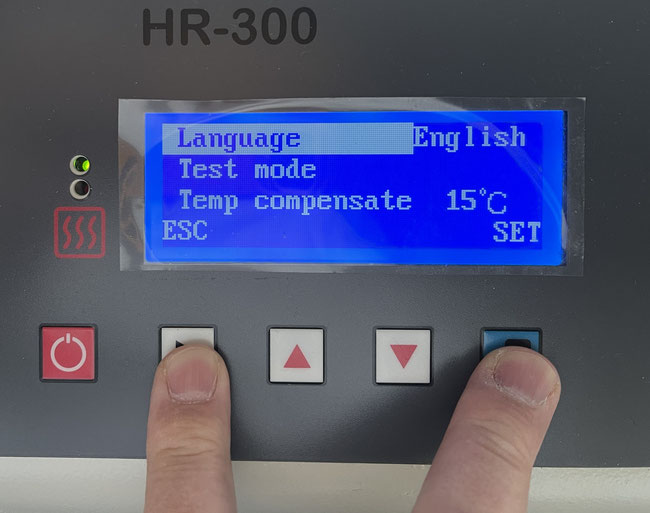

We carried out a temperature test and first calibrated the new oven in constant temperature mode.

The setup menu is accessed by pressing the Run and Enter buttons simultaneously.

A temperature deviation of 15 degrees was compensated. Then checked again in constant temperature mode.

The GC10 profile listed above was then used as the test.

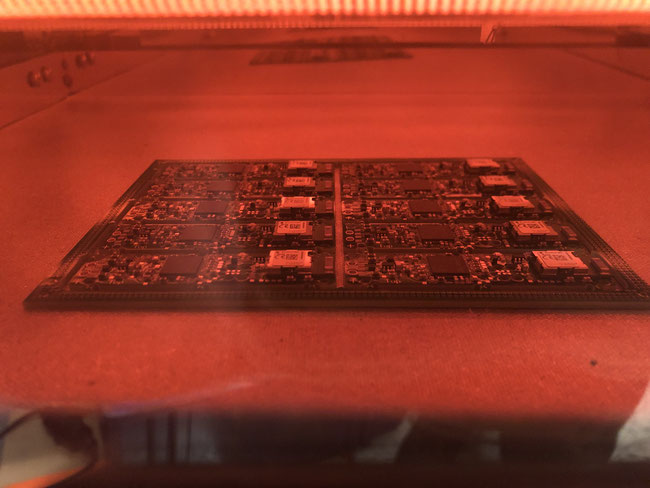

GALLERY

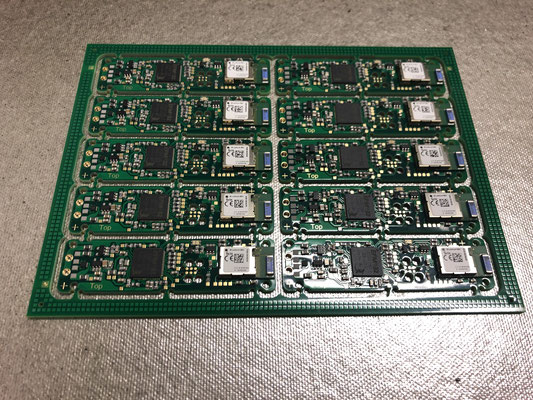

Nice demo job perfect result for hand placed samples

First demo job

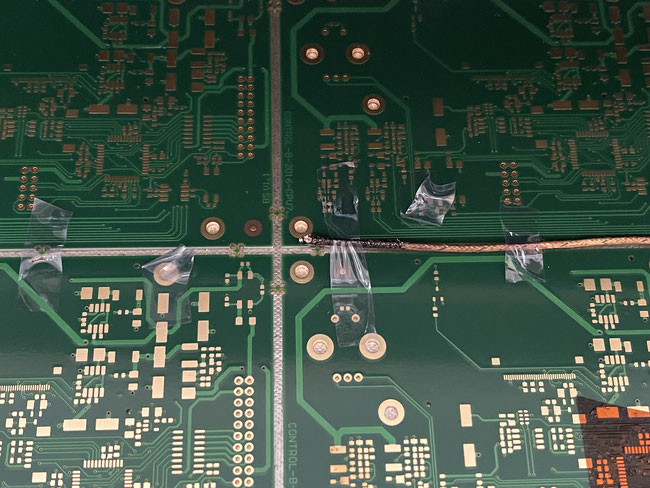

Oversized PCB demo job

All parts soldered fine except the IC's inside the copper plane but this is an design issue.

A reflow oven is a machine used in the process of surface mount technology (SMT) to attach electronic components to a printed circuit board (PCB). It works by heating the PCB and components to a temperature high enough to melt the solder paste, which then reflows and solidifies to form a permanent connection between the components and the PCB.

Here is a basic explanation of the reflow process:

-

Preheat: The reflow oven begins by heating the PCB to a low temperature to remove any moisture and prepare it for the soldering process.

-

Ramp-up: The temperature is gradually increased to a specified temperature range, known as the "preheat zone", where the solder paste starts to become active.

-

Soak: The temperature is held within the preheat zone for a specified time to allow the solder paste to become evenly distributed and the components to stabilize.

-

Reflow: The temperature is then rapidly increased to a higher temperature, known as the "reflow zone", where the solder paste reaches its melting point and reflows.

-

Cooling: The temperature is then gradually decreased to a safe level, where the solder solidifies and the components are firmly attached to the PCB.

The entire process is carefully controlled to ensure consistent results and to prevent damage to the components or the PCB. The temperature profile of the reflow process is typically determined based on the type of solder paste and components being used.