- Home

- Home_de

- Products

- Downloads

- Forum

- Sales

- News

- Exhibitions

- Know how

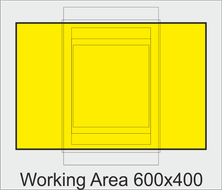

- Building VP-2500D workingtable

- First installation

- VP-2500D 0402 placement test

- Mark detection demo

- Placing TQFP48 demo

- 0201 Placement

- BGA Alignment

- FAQ-Feeder-settings

- Soldering-FAQ

- Controller Upgrade V1 to V2

- How to upgrade to 19 slot nozzle changer

- First setup and placement job

- How to build Electronics

- For Makers

- Questions & Answers

- Software

- Repair Documents

- References

- Service

- Spare-Parts

- Videos

- Warranty

- Kompetenz

- Competence

- Cookie Policy

- Privacy Policy

- About

- PANDA-design-contest

- New V3 software

VisionPlacer are professional pick and place machine aimed for prototype and small production.

Naming conventions:

S = Single head, D = Double head entry machine, DP = Double head belt precision machine, HP = High Precision ball screw spindle machine using AC servos an shaft encoders.

2H = 2 head, 4H = quad 4 head, 4R = 4 heads in a row

CL-22 / 32 / 62 / 64 = Number of 8mm wide CL feeder slots Yamaha (tm) compatible

We have stock machines could ship within one week!

New Electrical Feeder option for our 4R / Pecker / Raptor machines.

Electrical CL Feeder speed up the PNP processing because the need only 5ms feed time instead of >100ms. This makes a big difference if using 4/8 heads. The head don't need to wait over feeder to pickup same part to other heads. Second advantage is for very small parts you receive no part shaking during feed process.

Basic PNP machines for small labs

- 2 Heads

- Belt drive

- Closed loop Stepper motors X/Y

- Profiled guide ways

- Stable construction

- Dispenser option available

- >=0.6mm pin pitch

- 0402 - 30x30mm

HP Spindle pick and place machines

- 2 / 4 Heads

- Ball screw spindle drive

- AC Servo motors X/Y

- Closed loop position

- Profiled guide ways

- Stable construction

- Dispenser option available

- >=0.45mm pin pitch

- 0201 - 30x30mm

Click on the model name to open the product page!

Entry level belt driven desktop pick and place machines

Entry line belt driven PNP with CL Feeder bay

High precision pick and place machines

The unbeatable solution for many feeders in a small space with a large working range and high precision.

The "H" machines differ mainly in the analogue camera system which offers a lower resolution and field of view.

VP-2800HP-CL62-2H

VP-2800HP-CL64-4H

Premium Line PNP machine

Up to 64CL feeder plus 35x8mm push feeder and 4x vibration feeder possible.

Dispenser head option available.

Optional 19 slot nozzle changer for 4 head version.

Paste Dispenser

AC Servo Spindle Machine

Direct position feed back

The unbeatable solution for many feeders in a small space with a large working range. Also with high camera resolution and increased precision.

The "R" pick-and-place machines are equipped with industrial USB cameras that offer higher resolution and faster alignment. The field of view of the cameras is extended which allows components of

up to 35x35mm in the standard, and 40x40 with extended lens system.

All machines are equipped with a high-speed camera, which allows the alignment of components of all heads during the fly-by, without the placement head having to stay above the camera.

VP-2800HP-CL64-4R

Premium Line Pick and Place machine

Up to 64CL feeder plus 35x8mm push feeder and 4x vibration feeder possible.

High speed HP USB cameras plus

Fly by camera adjustment.

Optional conveyor.

Optional 19 slot nozzle changer.

Dispenser head option available.

Ask for machine delivery time this is mostly a stock machine!

HD Vision System

Paste Dispenser

AC Servo Spindle Machine

Direct position feed back

Fly By Visual Alignment

VP-2800HP-CL64-4RCV

The VP-2800HP-CL64-4RCV has 3 zone conveyor and SMEMA interfaces on both sides. The machine performance is the same like VP-2800HP-CL64-4R except west push feeders are missing.

SMALLSMT PECKER

High end PNP machine

Embedded industrial PC.

CAN bus inside for reduced cabling.

Intelligent placement head.

Pneumatics mounted on head for easy access.

Up to 64CL feeder plus 35x8mm push feeder and 4x vibration feeder possible.

High speed HP USB cameras plus

Fly by camera adjustment.

Optional 19 slot nozzle changer.

Dispenser head option available.

Ask for machine delivery time this is mostly a stock machine!

Our New PNP machine PECKER has new intelligent 4 line PNP head including vacuum generators and CAN based controller system for reduced cabling.

It use our new fast V3 controller and has increased resolution of 10 microns.

And it's still for office use and can pass a 80cm door!

SMALLSMT RAPTOR

Our New PNP machine RAPTOR has new intelligent 8 line PNP head with independent z-axis moving heads, including vacuum generators and CAN based controller system for reduced cabling.

It use our new fast V3 controller and has increased resolution of 10 microns.

Dispenser head option for all VP-2XXX pick & place machines

Our dispensing head is a simple and inexpensive solution extending the functionality of your PNP machine. The dispensing of adhesive and paste is possible with this.

PCB HD Microscope for PCB Visual Inspecion System

If you are looking for a PCB control solution that offers high resolution and fast focusing, please contact us.

Reflow oven DARK IR & AIR CIRCULATION

The HR-300 is an extremely user-friendly convection oven suitable for lead-free SMD soldering of printed circuit boards.

It has many advantages especially fully controlled reflow cycle in closed oven!

Building your own electronics production line requires careful planning and execution. Here are the steps to guide you:

- Define your production goals: Determine what type of electronics you want to produce, the quantities you plan to produce, and the target market.

- Research and select components: Choose the components you will use in your electronics, including processors, sensors, actuators, and others. Research suppliers and compare prices and delivery times.

- Design the electronics: Use a computer-aided design (CAD) program to create detailed schematics and layouts of your electronics. Verify that your designs meet all necessary safety and performance standards.

- Prototype and test: Build a small batch of your electronics to test their functionality and refine your designs as needed.

- Choose and set up your production equipment: Select the necessary production equipment, such as pick and place machines, soldering equipment, and testing equipment. Set up the equipment in a clean and organized workspace.

- Develop production processes and procedures: Develop processes and procedures for producing your electronics, including assembly, testing, and quality control.

- Train your workforce: Hire and train a team of workers to operate the equipment and perform the production processes.

- Source materials: Establish relationships with suppliers and source materials, such as circuit boards, components, and packaging materials.

- Launch production: Start producing your electronics, monitoring production quality and making adjustments as needed.

- Continuously improve: Regularly review your production processes and make improvements to increase efficiency, reduce costs, and improve product quality.

Key features of pick and place machines

- High precision: PNP machines are designed to place components accurately and consistently onto the circuit board.

- High speed: PNP machines can process a large number of components in a short amount of time, increasing production efficiency.

- Multiple feeder options: PNP machines can support multiple feeder types, such as tape, tray, and tube feeders, to accommodate a wide range of components.

- Vision system: Some PNP machines come equipped with a vision system that can recognize and place components accurately, even if they are misaligned or oriented incorrectly.

- Flexibility: Many PNP machines can be programmed to handle a wide range of components and board sizes, making them adaptable to different production requirements.

- User-friendly interface: Most PNP machines have a user-friendly interface that makes it easy for operators to change settings, input new programs, and monitor production.

- Maintenance-free: PNP machines are designed for low maintenance and to run continuously for extended periods without interruption.

- Error detection: Some PNP machines have built-in error detection systems that can detect and correct placement errors in real-time, reducing scrap and rework.