- Home

- Home_de

- Products

- Downloads

- Forum

- Sales

- News

- Exhibitions

- Know how

- Building VP-2500D workingtable

- First installation

- VP-2500D 0402 placement test

- Mark detection demo

- Placing TQFP48 demo

- 0201 Placement

- BGA Alignment

- FAQ-Feeder-settings

- Soldering-FAQ

- Controller Upgrade V1 to V2

- How to upgrade to 19 slot nozzle changer

- First setup and placement job

- How to build Electronics

- For Makers

- Questions & Answers

- Software

- Repair Documents

- References

- Service

- Spare-Parts

- Videos

- Warranty

- Kompetenz

- Competence

- Cookie Policy

- Privacy Policy

- About

- PANDA-design-contest

VP-2500HP pick and place machine push feeder

A pick and place machine need feeder lines to supply the components for the placement process.

Our machines can have a lot of feeder lines on 3 sides of the machine table.

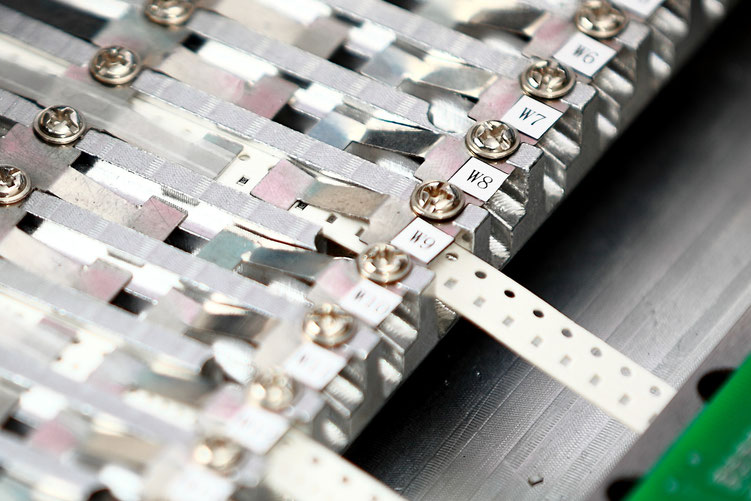

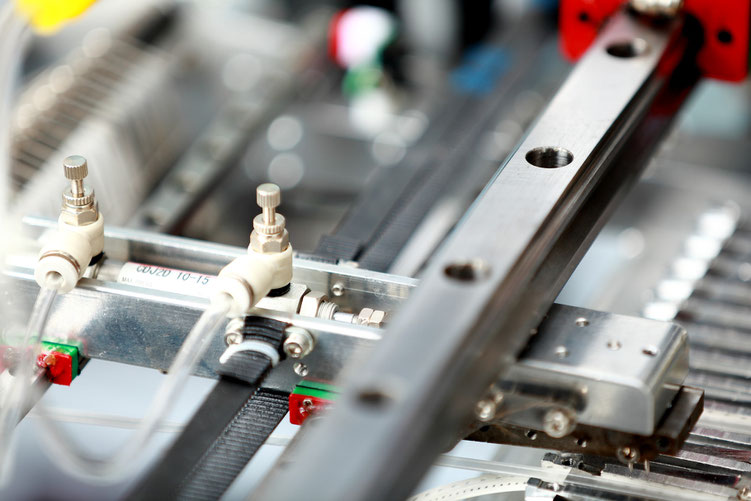

We use a pneumatic push feeder to feed 4mm on every push. The clear tape winder releases the tape, the push cycle starts and after that the winder pulls the clear tape back to open the pocket.

Every parameter is adjustable so you can modify the speed, travel width for the clear tape and pick up point and height.

Sometimes the springs need some adjustment if the opened pocket maybe covered by a side of the feeder spring.

The pneumatic cylinder moves the push feeder head in 2 cyles.

On each push feeder side we have a clear cover tape winder.

The tape goes through two sawtooth wheels, the big one has a clutch and will be driven by a center shaft.

Every small sawtooth wheel was held by a spring set. You can adjust the pressure by bending the springs.