- Home

- Home_de

- Products

- Downloads

- Forum

- Sales

- News

- Exhibitions

- Know how

- Building VP-2500D workingtable

- First installation

- VP-2500D 0402 placement test

- Mark detection demo

- Placing TQFP48 demo

- 0201 Placement

- BGA Alignment

- FAQ-Feeder-settings

- Soldering-FAQ

- Controller Upgrade V1 to V2

- How to upgrade to 19 slot nozzle changer

- First setup and placement job

- How to build Electronics

- For Makers

- Questions & Answers

- Software

- Repair Documents

- References

- Service

- Spare-Parts

- Videos

- Warranty

- Kompetenz

- Competence

- Cookie Policy

- Privacy Policy

- About

- PANDA-design-contest

- New V3 software

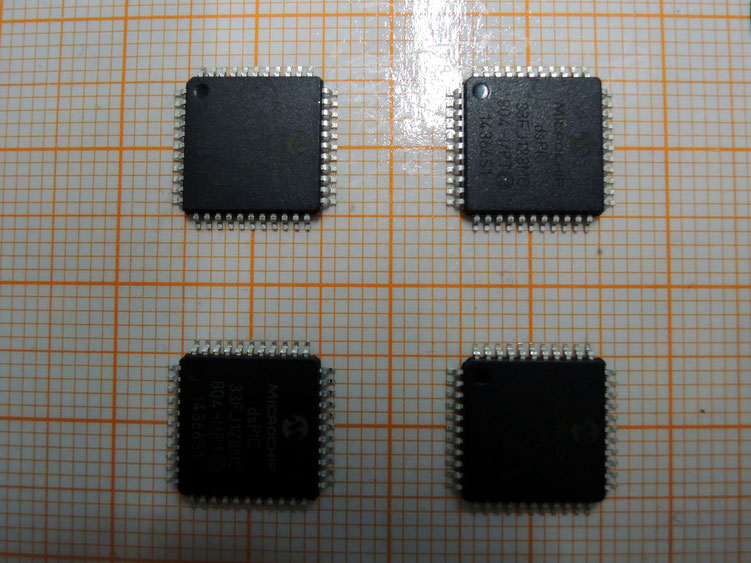

VP-2500D SMT Visual alignment demo for TQFP48

I like to show you the excellent vision system capabilitys of out VP-2500D machine software.

We used for test setup a special PCB having a grid paper on top and mark points too.

First the system do the board alignment and places 2x2 TQFP48 chips.

The bottom camera 2 at mid speed setting was used.

I programmed 2 positions and set a panel of 2 boards in PCB setup.

Vision Placer Software working demo

You can see the Vision Placer software working.

First I reset the tray feeder grid to set the machine to the first part position on pick up.

Then you see the start of the placement process.

The machine takes each part to bottom camera 2 and run the visual alignment.

After alignment was processed the part was placed.

VP-2500D placing TQFP48 parts using visual alignment

Nearly perfect result because I used CN0140 2.2mm nozzle it's a little to small to hold the component tight but it works!

Write a comment