- Home

- Home_de

- Products

- Downloads

- Forum

- Sales

- News

- Exhibitions

- Know how

- Building VP-2500D workingtable

- First installation

- VP-2500D 0402 placement test

- Mark detection demo

- Placing TQFP48 demo

- 0201 Placement

- BGA Alignment

- FAQ-Feeder-settings

- Soldering-FAQ

- Controller Upgrade V1 to V2

- How to upgrade to 19 slot nozzle changer

- First setup and placement job

- How to build Electronics

- For Makers

- Questions & Answers

- Software

- Repair Documents

- References

- Service

- Spare-Parts

- Videos

- Warranty

- Kompetenz

- Competence

- Cookie Policy

- Privacy Policy

- About

- PANDA-design-contest

- New V3 software

We offer high quality CL Feeder clones in different sizes.

Spare parts are availiable.

We offer discount if you order more feeders:

>= 10 pcs 3%,

>= 25 pcs 5%,

>= 100pcs 10%

CL Feeder 8mm wide

The 8mm CL feeder offer 3 different types and have fixed pitch.

- Standard for 0603 sizes up using 4mm pitch

- 0402 type using 2mm pitch

- 0201 type using 2mm pitch and better precision.

CL Feeder 12 / 16mm wide

Other wide feeders like 12mm and 16mm offer adjustable pitch setting.

Simple mechanical adjustment by changing a plate orientation allows to choose 4, 8, 12, 16mm pitch.

Videos showing how to change 12 / 16mm feeder pitch

CL Feeder 24 / 36mm wide

Our 24 and 32mm feeder use different mechanics to adjust pitch.

A simple saw tooth ladder allows to adjust the part pitch in 4mm steps.

After adjustment of cylinder you need to turn the winder drum anti clockwise until you hear a click, to adjust winder pitch too. Check adjustments by pressing manual feed button. Before the feeder is closed again, the sliding plate must be pushed forward and snap in when closing.

How to install CL Feeder

External Videos about CL feeder repair and calibration

CL feeder calibration

Space requirements for CL Feeder

All CL feeder bay slots are for 8mm CL feeder designed.

If you need to use all 64 slots only 8mm feeder possible.

For 12 and 16mm wide CL feeder we need 3 slots for the first feeder and 2 slots for each following.

The 24mm CL feedr needs 3 slots.

12 / 16mm CL-Feeder

24mm CL Feeder

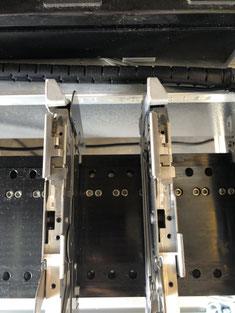

Special for our machines 4x wide slots on CL6X machines

Machine can take up to 4x 24mm feeder without loosing a slot.

VP2800HP-CL6X CL feeder layout example

FC120 CL Feeder Cart offers 120x 8mm wide slots

The new feeder cart offers a stable storage for CL Feeder on a small space.

Feeder bank made from anodized aluminium.

Optional heavy duty rollers allow a movable storage system.

You can add otional 4x heavy duty rollers.

FC120 CL Feeder Cart

The new feeder cart offers a stable storage for 120x 8mm wide CL Feeder on a small space.

Feeder bank made from anodized aluminium.

Optional heavy duty rollers allow a movable storage system.

$982.50

Final price, free shipping to selected countries

Free shipping to the following countries: Afghanistan, Albania, Andorra, Angola, Anguilla, Antarctica, Antigua and Barbuda, Armenia, Netherlands Antilles, United Arab Emirates , Algeria, American Samoa, Argentina, Aruba, Australia, Austria, Azerbaijan, Bahamas, Bahrain, Bangladesh, Barbados, Belarus, Belgium, Belize, Benin, Bermuda, Bhutan, Bolivia, Bosnia and Herzegovina, Botswana, Bouvet Island, Brazil, British Indian Ocean Territory, British Virgin Islands, Brunei, Bulgaria, Burkina Faso, Burundi, Cambodia, Cameroon, Canada, Cape Verde, Cayman Islands, Central African Republic, Chad, Chile, China, Christmas Island, Cocos [Keeling] Islands, Colombia, Comoros, Congo - Brazzaville, Congo - Kinshasa, Cook Islands, Costa Rica, Côte d’Ivoire, Croatia, Cuba, Cyprus, Czech Republic, Denmark, Djibouti, Dominica, Dominican Republic, Ecuador, Egypt, El Salvador, Equatorial Guinea, Eritrea, Estonia, Ethiopia, Falkland Islands, Faroe Islands, Fiji, Finland, France, French Guiana, French Polynesia, French Southern Territories, Gabon, Gambia, Georgia, Germany, Ghana, Gibraltar, Greece, Greenland, Grenada, Guadeloupe, Guam, Guatemala, Guinea, Guinea-Bissau, Guyana, Haiti, Heard Island and McDonald Islands, Honduras, Hong Kong SAR China, Hungary, Iceland, India, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, Kiribati, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Lesotho, Liberia, Libya, Liechtenstein, Lithuania, Luxembourg, Macau SAR China, Macedonia, Madagascar, Malawi, Malaysia, Maldives, Mali, Malta, Marshall Islands, Martinique, Mauritania, Mauritius, Mayotte, Mexico, Micronesia, Moldova, Monaco, Mongolia, Montenegro, Montserrat, Morocco, Mozambique, Myanmar [Burma], Namibia, Nauru, Nepal, Netherlands, New Caledonia, New Zealand, Nicaragua, Niger, Nigeria, Niue, Norfolk Island, Northern Mariana Islands, North Korea, Norway, Oman, Pakistan, Palau, Palestinian Territories, Panama, Papua New Guinea, Paraguay, Peru, Philippines, Pitcairn Islands, Poland, Portugal, Puerto Rico, Qatar, Réunion, Romania, Russia, Rwanda, Saint Barthélemy, Saint Helena, Saint Kitts and Nevis, Saint Lucia, Saint Martin, Saint Pierre and Miquelon, Saint Vincent and the Grenadines, Samoa, San Marino, São Tomé and Príncipe, Saudi Arabia, Senegal, Serbia and Montenegro, Seychelles, Sierra Leone, Singapore, Slovakia, Slovenia, Solomon Islands, Somalia, South Africa, South Georgia and the South Sandwich Islands, South Korea, Spain, Sri Lanka, Sudan, Suriname, Svalbard and Jan Mayen, Swaziland, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Timor-Leste, Togo, Tokelau, Tonga, Trinidad and Tobago, Tunisia, Turkey, Turkmenistan, Turks and Caicos Islands, Tuvalu, Uganda, Ukraine, United Kingdom, United States, Uruguay, U.S. Minor Outlying Islands, U.S. Virgin Islands, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Wallis and Futuna, Western Sahara, Yemen, Zambia, Zimbabwe Show more Show less

- 47 kg

- Available

- Ships within 1-3 days1

FC160 CL Feeder cart offers 160x 8mm wide slots

The new FC160 feeder cart offers a stable storage for CL Feeder on a small space.

Feeder bank made from anodized aluminium.

Optional heavy duty rollers allow a movable storage system.

You can add otional 4x heavy duty rollers.

FC160 CL Feeder Cart

The new feeder cart offers a stable storage for CL Feeder on a small space.

Feeder bank made from anodized aluminium.

Optional heavy duty rollers allow a movable storage system.

$1,162.00

Final price, free shipping to selected countries

Free shipping to the following countries: Afghanistan, Albania, Andorra, Angola, Anguilla, Antarctica, Antigua and Barbuda, Armenia, Netherlands Antilles, United Arab Emirates , Algeria, American Samoa, Argentina, Aruba, Australia, Austria, Azerbaijan, Bahamas, Bahrain, Bangladesh, Barbados, Belarus, Belgium, Belize, Benin, Bermuda, Bhutan, Bolivia, Bosnia and Herzegovina, Botswana, Bouvet Island, Brazil, British Indian Ocean Territory, British Virgin Islands, Brunei, Bulgaria, Burkina Faso, Burundi, Cambodia, Cameroon, Canada, Cape Verde, Cayman Islands, Central African Republic, Chad, Chile, China, Christmas Island, Cocos [Keeling] Islands, Colombia, Comoros, Congo - Brazzaville, Congo - Kinshasa, Cook Islands, Costa Rica, Côte d’Ivoire, Croatia, Cuba, Cyprus, Czech Republic, Denmark, Djibouti, Dominica, Dominican Republic, Ecuador, Egypt, El Salvador, Equatorial Guinea, Eritrea, Estonia, Ethiopia, Falkland Islands, Faroe Islands, Fiji, Finland, France, French Guiana, French Polynesia, French Southern Territories, Gabon, Gambia, Georgia, Germany, Ghana, Gibraltar, Greece, Greenland, Grenada, Guadeloupe, Guam, Guatemala, Guinea, Guinea-Bissau, Guyana, Haiti, Heard Island and McDonald Islands, Honduras, Hong Kong SAR China, Hungary, Iceland, India, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, Kiribati, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Lesotho, Liberia, Libya, Liechtenstein, Lithuania, Luxembourg, Macau SAR China, Macedonia, Madagascar, Malawi, Malaysia, Maldives, Mali, Malta, Marshall Islands, Martinique, Mauritania, Mauritius, Mayotte, Mexico, Micronesia, Moldova, Monaco, Mongolia, Montenegro, Montserrat, Morocco, Mozambique, Myanmar [Burma], Namibia, Nauru, Nepal, Netherlands, New Caledonia, New Zealand, Nicaragua, Niger, Nigeria, Niue, Norfolk Island, Northern Mariana Islands, North Korea, Norway, Oman, Pakistan, Palau, Palestinian Territories, Panama, Papua New Guinea, Paraguay, Peru, Philippines, Pitcairn Islands, Poland, Portugal, Puerto Rico, Qatar, Réunion, Romania, Russia, Rwanda, Saint Barthélemy, Saint Helena, Saint Kitts and Nevis, Saint Lucia, Saint Martin, Saint Pierre and Miquelon, Saint Vincent and the Grenadines, Samoa, San Marino, São Tomé and Príncipe, Saudi Arabia, Senegal, Serbia and Montenegro, Seychelles, Sierra Leone, Singapore, Slovakia, Slovenia, Solomon Islands, Somalia, South Africa, South Georgia and the South Sandwich Islands, South Korea, Spain, Sri Lanka, Sudan, Suriname, Svalbard and Jan Mayen, Swaziland, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Timor-Leste, Togo, Tokelau, Tonga, Trinidad and Tobago, Tunisia, Turkey, Turkmenistan, Turks and Caicos Islands, Tuvalu, Uganda, Ukraine, United Kingdom, United States, Uruguay, U.S. Minor Outlying Islands, U.S. Virgin Islands, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Wallis and Futuna, Western Sahara, Yemen, Zambia, Zimbabwe Show more Show less

- 54 kg

- Available

- Ships within 1-3 days1