VP-30XXD / T Beta Zone

MODULAR SYSTEM

This machine is rock solid, modular, extendable and future safe because you are able to upgrade head unit and add feeder slots after time.

MEASUREMENT SYSTEM

We don't assume the machine head position, we know because of scales on X / Y axis measuring 0.01mm at 0.02mm precision.

3D PLACEMENT POSSIBLE (MID)

Our Machine is able to place parts on different Z height positions so 3D PCB's are possible for placement.

WIDE PART RANGE

The part range will be from 0201 up to 30x30mm components and Z axis can travel 30mm so tall parts are no problem too.

ANTI COLLISION

We support anti collision strategy by intelligent head retract mode the machine moves the head origin up when high parts need to be placed. We use part height sorting so it will move up when tall parts where placed before.

HIGH QUALITY

We build and design VP-30XX machines in Germany!

The pneumatic system components are from FESTO, servo system from Mitsubishi, Power supplies from Meanwell, Guide lines from HIWIN.

All this components can be bought around the world and replaced.

Technical Data:

Dimensions:

Base machine 935 x 1050 x 430mm, including Feeder 1160 x 1485 x 430mm

Machine including cover 935 x 1050 x 485mm, including Feeder 1160 x 1485 x 485mm

Weight for the base unit is 75Kg , Stand 28Kg, Cover 35Kg, each feeder 1,4Kg

Nozzles:

We use CP45 Samsung nozzles.

1x 10 slot nozzle changer carts.

So it's possible to use 10 nozzles in one placement job including the option to use the same nozzle on both heads.

Dispenser:

The optional third head can be used independently to apply glue or paste to the PCB.

The Dispenser controller is integrated in our machine!

Feeder System:

28x 8mm Yamaha CL feeder cassettes on South (can get closed to extend working area!)

28x 8mm Yamaha CL feeder cassettes on North (can get closed to extend working area!)

30x 8mm Yamaha CL feeder cassettes on East plus

6x 8mm / 12mm / 16mm Yamaha CL feeder cassettes on East totally 36.

3x small tray feeders possible one in front of the West feeder bank and two between the cameras!

Totally up to 92x 8mm or 86x 8mm and 6x 12/16mm Yamaha CL feeder cassettes on a single machine!

We support standard CL vibration feeder!

PCB Area:

400x400mm working area for PCB and trays. ( expandable if feeder bays closed on North and South up to 700x400mm working area

using only East feeder bank)

Fast clamp mechanic to fix the PCB inside PCB holder.

Mounting holes to fix tray holders or custom PCB holders.

Position System:

Belt driven X / Y axis.

Spindle drive for all Z axis.

Closed loop positioning using linear scale encoder system on X and Y axis.

Closed loop positioning using stall detection on Z axis. (TRINAMIC)

Stepper motors standard on X and Y axis (PRO) but servo (PREMIUM) motors upgradeable!

We use MELSERVO Mitsubishi Japan servo motors.

Placement speed:

Premium

single Head 3500cph

double Head 5000cph

Depend on different part count and part distances!

Cameras:

2x USB 2.0 2MP bottom IDS Industrial cameras

1x USB 2.0 2MP top IDS Industrial camera

Optional components:

- Dispenser head including integrated controller

- Stand made from steel

- Machine cover using 2 doors including safety control system and coded switches

- Feeders stock system mounted inside the stand using slide out plate

- Monitor and keyboard holder

- Integrated high performance PC running Linux and supporting for up to 5 cameras.

MADE IN GERMANY

VP-30XXD Model list

PREMIUM Machine has servo drives for X and Y axis

Linear scales on X,Y,Z axis for closed loop positioning

- VP-3028D PREMIUM with 28 pneumatic feeders ports (28x South)

- VP-3056D PREMIUM with 56 pneumatic feeders ports (28x South + 28x North)

- VP-3064D PREMIUM with 64 pneumatic feeders ports (28x South + 36x East)

- VP-3092D PREMIUM with 92 pneumatic feeders ports (28x South + 28x North + 36x East)

EAST Feeder has 6 wider slots spacing to take 12 and 16mm tapes without losing a slot!

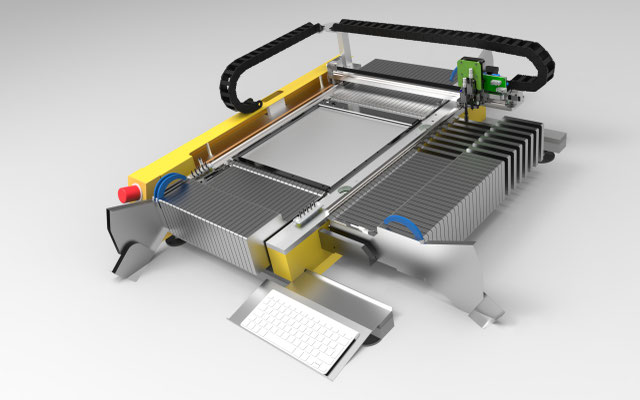

UHQ picture of VP-3092T

Triple head system and 28 Feeder lines on North ans South, 30x8mm + 6x 16mm on East side.

Totally 92 Yamaha CL feeder slots showing optional stand.

Feeder variants VP-30XXT

36 Slot Feeder module

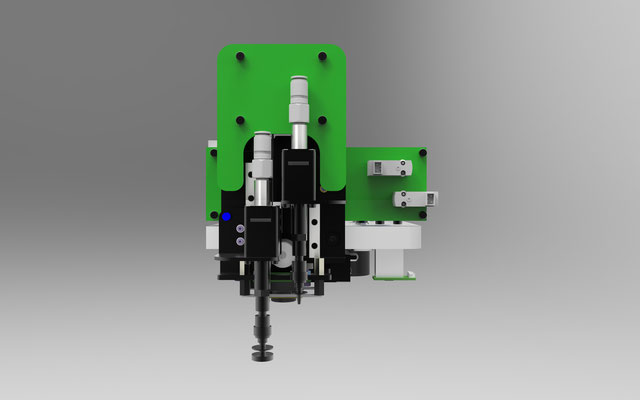

Upgrading VP-30XXD to 3 head system using spindle drive

We are currently upgrading the head to use a a third head for dispenser use.

The Musashi Dispenser system can be combined to apply glue or paste to your PCB.

MUSASHI SMART SHOT MS-1/MS-1D (economy) or ML-5000XII (pro)

All heads now can be moved individually that means we can move heads up if high parts need to be placed to avoid collisions. The total Z axis travel way is now 30mm!

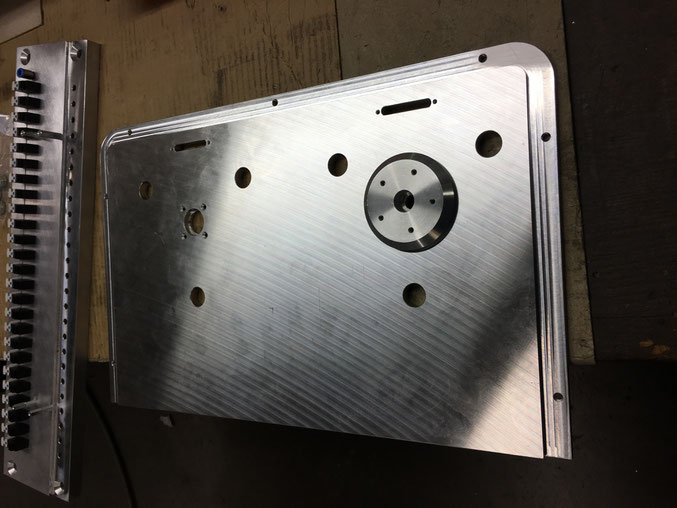

Check the build quality of our machine this is the first prototype! MADE IN GERMANY

VP-30XXD final design update

5 Slot nozzle changer design on both sides

Fast clamping PCB holder

VP-3082D PRO / PREMIUM without cover

VP-3057D PRO / PREMIUM without cover

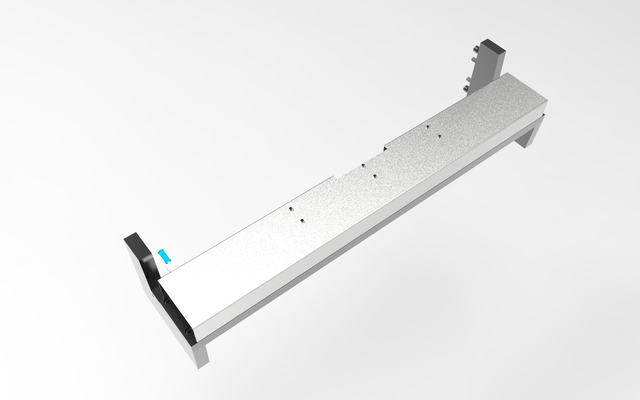

VP-30XXD Feederblock 25 Slots

VP-30XXD Basic machine final design

VP-3000D Final head design

VP-30XXD first production pictures 28.10.2016

25 slot feeder cart

Integrated tube less feeder cart including Festo valves and electronics.

Nozzle changer cart

Up to 10 nozzles can be used in one placement job because of 2x 5 slot nozzle changer carts in our system.

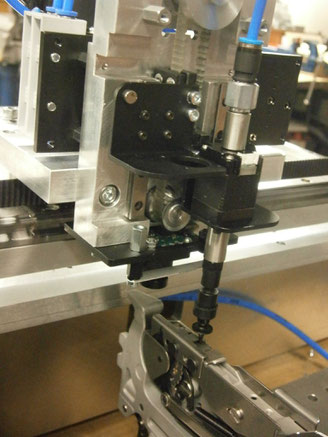

PNP head

Our pick and place head includes complete vacuum system and embedded control.

X axis assembly

Mono rail belt system including integrated belt tensioner system below the head assembly.

Heavy body parts

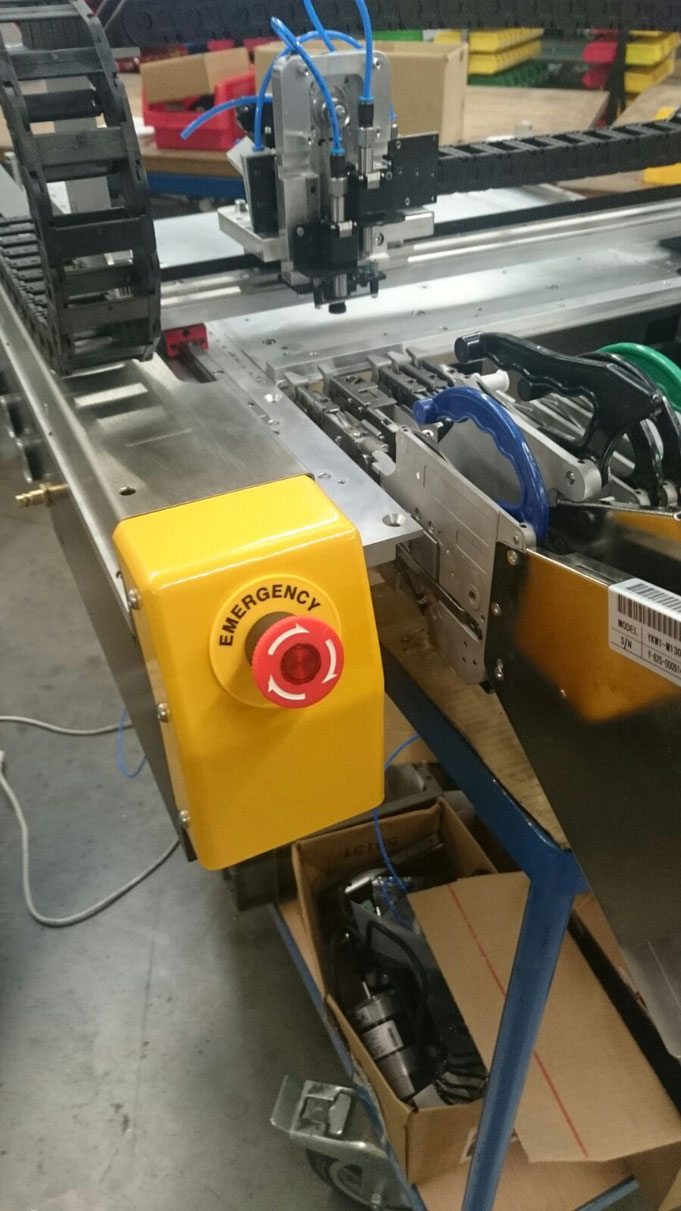

Left side of machine including the safety switch off.

Machine working plate

Diskfeeder assembly plate